Prefabrication

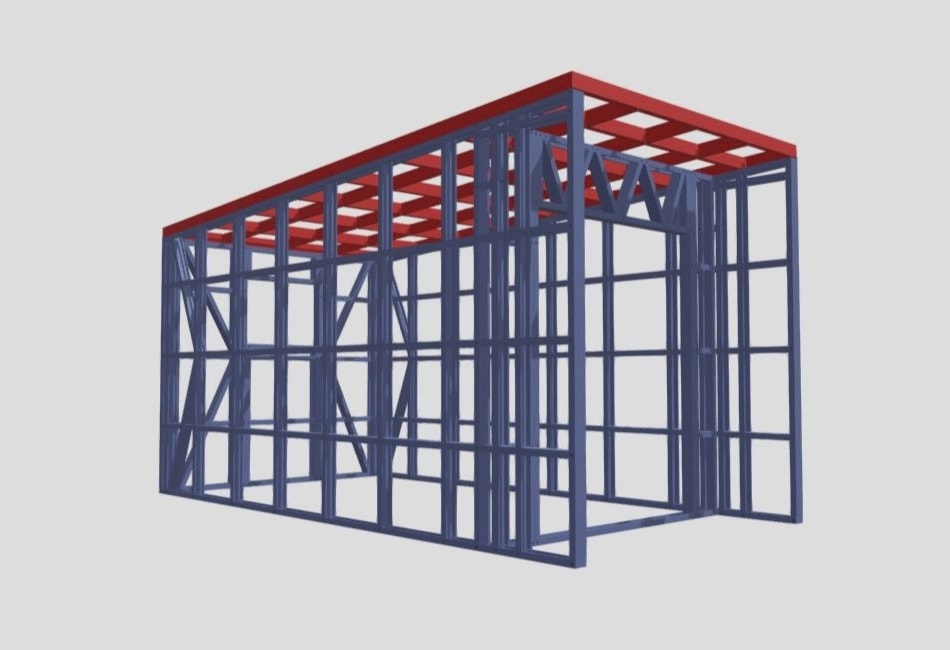

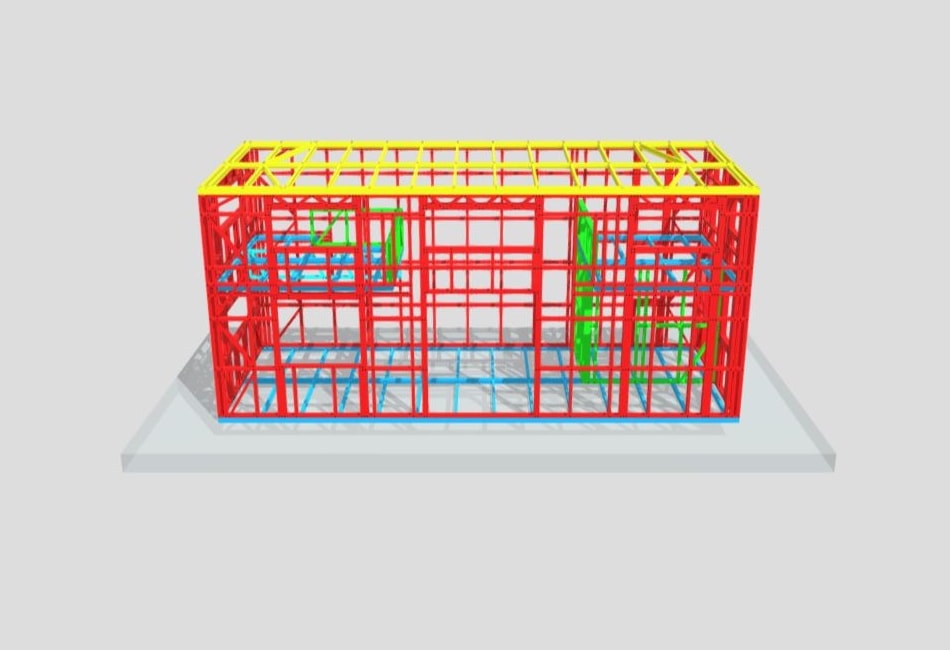

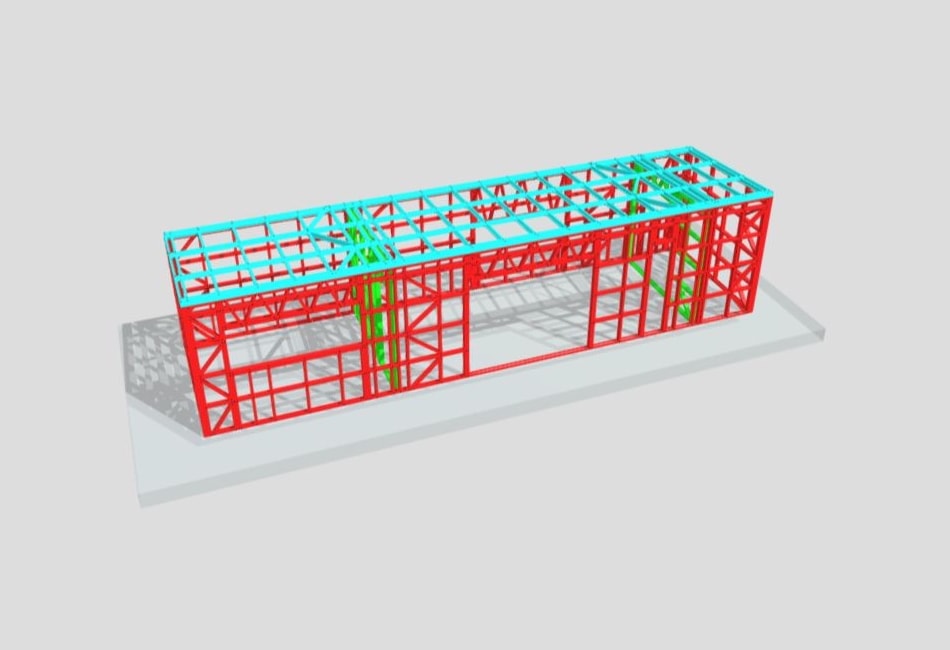

Steel Frame Solutions

Prefabrication

Steel Frames Ready To Go

A growing number of building professionals are using prefabrication techniques to work smarter, faster, and safer – and the material they choose to work with can magnify those benefits.

Cold-formed steel (CFS) framing is an ideal choice because it is non-combustible, lightweight, and cut to precise specifications.

Prefabrication

by the Numbers

Prefabrication has been an established construction method for over 60 years.

Today more building professionals are making the switch, as they see the productivity, sustainability, cost and safety benefits of the process.

Who is using

prefabrication?

Who is using pre fabricated steel frames?

84% of Contractors

90% of Engineers

76% of Architects

Data sourced from BuildSteel

Benefits of using

Prefabrication

AEC professional report that project schedules decrease (35% saw a decrease of 4 weeks or more)

Report that construction site waste decrease (44% saw a decrease of 5% or more)

Report that project budgets decrease (41% saw a decrease of 6% or more)

Report an increase in site safety

Data sourced from BuildSteel

Factors driving current

use of prefabrication

- Contractors 92%

- Engineers 70%

- Architects 68%

- Contractors 85%

- Engineers 60%

- Architects 52%

- Contractors 70%

- Engineers 43%

- Architects 40%

Data sourced from BuildSteel

Factors driving future

use of fabrication

Save Time

Owner Demand

Competitive Market Advantage

Better Quality Control

Data sourced from BuildSteel

Why choose

cold-formed steel framing for prefabrication projects

Lightweight and Easy to Install

30% Lighter Than Wood

Non-Combustible

Low Fire Risk

Efficient

50% Faster Compared to Stick-frame Constructions

Durable

No Knots or Inconsistencies CFS Will Not: Shrink, Split, Warp, Crack, Creep

Exact

Members Cut to Exact Lengths Frequently within 1.6mm