Architects

Steel Frame Solutions

For Architects

How is designing with Light Gauge SAteel Framing different to traditional materials?

As the Architect, you may not yet be familiar designing projects with Light Gauge Steel Framing (LGSF) systems.

However, it’s generally the same principle, with some subtle differences. Some aspects are simpler using LGSF as the lintel and bracing details are available in the design.

There is a lot more design flexibility as well due to the non-combustible makeup of the materials. Plus, the higher strength to weight ratio reduces the need for extra and load bearing walls and columns providing longer spans.

Being up to 70% lighter depending on the panel or joist design, the weight advantages can assist for soil types and slab design.

We work to the NASH standards (the National Association of Steel Framed Housing) which is intended to be an alternative solution verification method to the NZ Building Code in conjunction with NZ3604. Which can provide span tables and other details to assist you with your designs.

Making the switch to

steel frame and truss

Builders are steering their clients to LGSF as the better choice for building due to the many advantages to them when working with LGSF. In Australia as you are well aware most residential construction uses LGSF and it’s gaining popularity in New Zealand year on year, as well as globally.

Find out more by contacting us for a discussion on the benefits of working with LGSF.

Steel Frames Are Better To

Work With

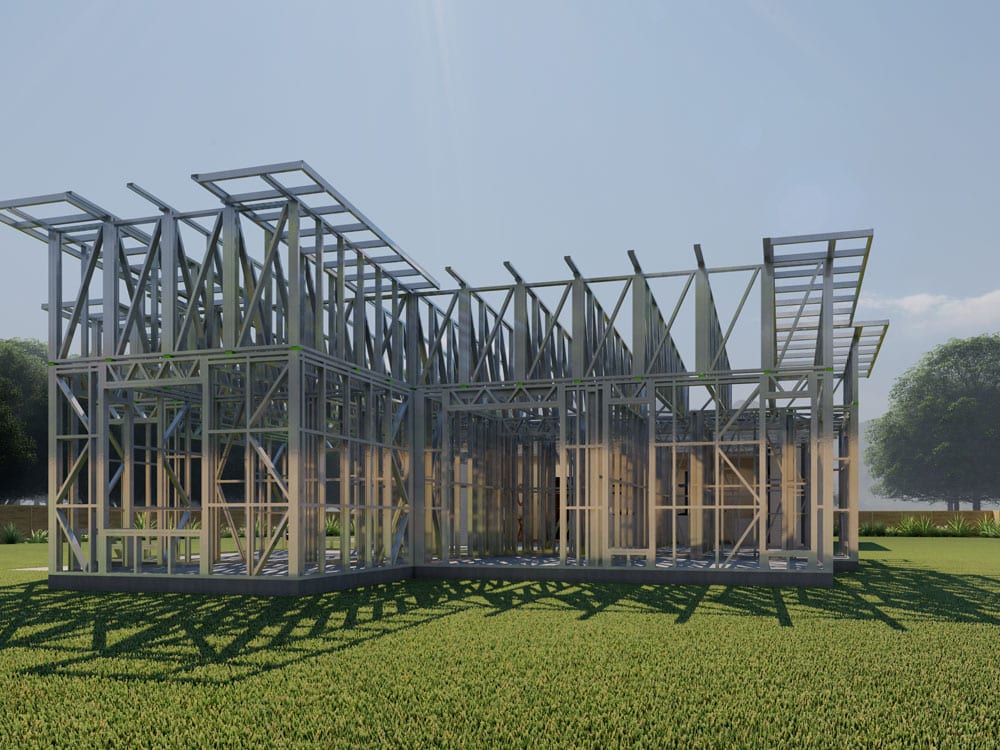

Working with commercial grade galvanized structural steel has some major benefits.

The slender profile of steel, its strength and light weight makes it an ideal option and no cranes are required to assemble the framework, which saves time and money.

Prefabricated frames are easy and quick to assemble and on-site wastage is almost eliminated. Frames fit together with logic and simplicity and being dimensionally stable, once erected they will not move or warp. Reduced waste on building sites means fewer bins are required.

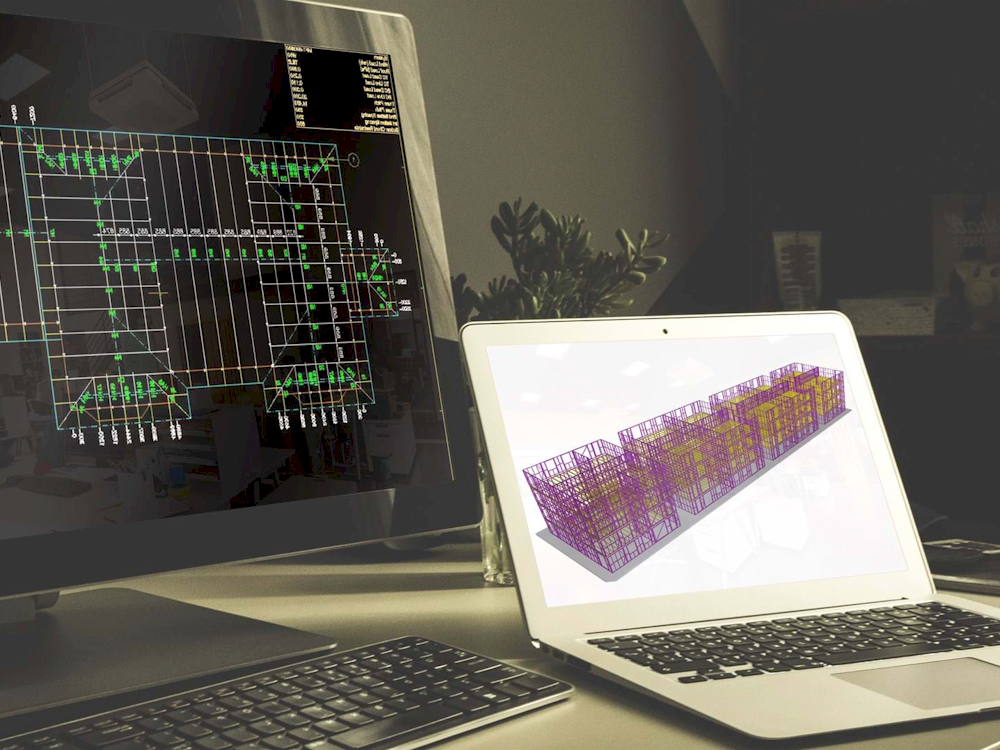

All our steel frames are designed and inspected by professional engineering consultants and architects to ensure Building Code Compliance in all aspects. Every project of Steel Frame Solutions can be covered by third party engineer’s producer statements PS1 and PS4 for council consented plans if required.

You may be wondering

why switch to steel?

Why switch to steel when for hundreds of years timber’s done the job?’

"The timber houses of the past were built with heart timber, either native or pine, clad in building paper and with wall and roof cavities that could “breathe” and were relatively lightly insulated. This protected the timber from condensation and hence ensured its durability. Modern houses have claddings and building wraps that don’t protect from condensation to the same extent, the walls are highly insulated which restricts airflow and the timbers are “young crop” Pinus Radiata which is much less durable, sometimes with surface only treatment against rot and borer. Steel is an inorganic man-made engineered product that is much better suited to retaining durability in modern house construction and has a proven track record of this for over 60 years in NZ. Furthermore, it does not absorb water and change dimensionally meaning no cracking of gypsum board linings."

National Association of Steel-Framed Housing Inc

benefits when

building with Steel

For a full list of benefits when building with Steel including health and environmental benefits, be sure to check out Why Steel Frames.

You can also check out – “10 Ways Cold-Formed Steel Framing Can Lower Your Total Construction Costs” prepared by BuildSteel.

BuildSteel is powered by the Steel Framing Industry Association (SFIA) dedicated to educating building professionals on the use of cold-formed steel (CFS) framing as a sustainable and cost-effective building solution.

Give us a call to discuss your next project.

Steel Frame Solutions

Why Steel Frames

No Toxic Chemicals

No Mould

No Rot

No Termites

No Gases & Vapours

No Shrinking, Cracking, Splitting, Creeping

No Bowing, Bending, Warping, Twisting or Movement

No Drying Out Required

Not Affected By Rain

No Rust

Non Combustible